Vinyl Ester coating

Vinyl Ester coating: protect industrial applications

In industrial environments where aggressive chemicals, high temperatures and mechanical stress come together, reliable protection of crucial installations is essential. A frequently used solution in these circumstances is the Vinyl Ester coating . This advanced coating technique is widely used in the Netherlands, particularly in sectors such as the chemical industry, food production, energy and water treatment.

Applications of Vinyl Ester coatings

The application of a Vinyl Ester coating is particularly suitable for environments where traditional coatings such as epoxy or polyester are not sufficient. Think of storage tanks, reactor vessels, pipes, floors and containment tanks that come into contact with aggressive acids, alkalis, solvents or organic substances. Due to their excellent chemical resistance, Vinyl Ester coatings are a logical choice for companies that operate with strong cleaning agents, acids or solvents.

Even at high temperatures, this coating maintains its performance. Where other coatings can crack or decompose due to heat, Vinyl Ester coating remains stable and protective, even under thermal stress up to 120 °C. This also makes the system ideal for installations that have to deal with cyclic heating or fluctuating process conditions.

Benefits at a glance

- Excellent chemical resistance. Especially to acids and solvents.

- High temperature resistance. ideal for dynamic production environments.

- Strong adhesion to concrete and steel

- Flexible and tear-resistant , even under mechanical stress

- Long lifespan , resulting in lower maintenance costs in the long term

Installation by our specialists

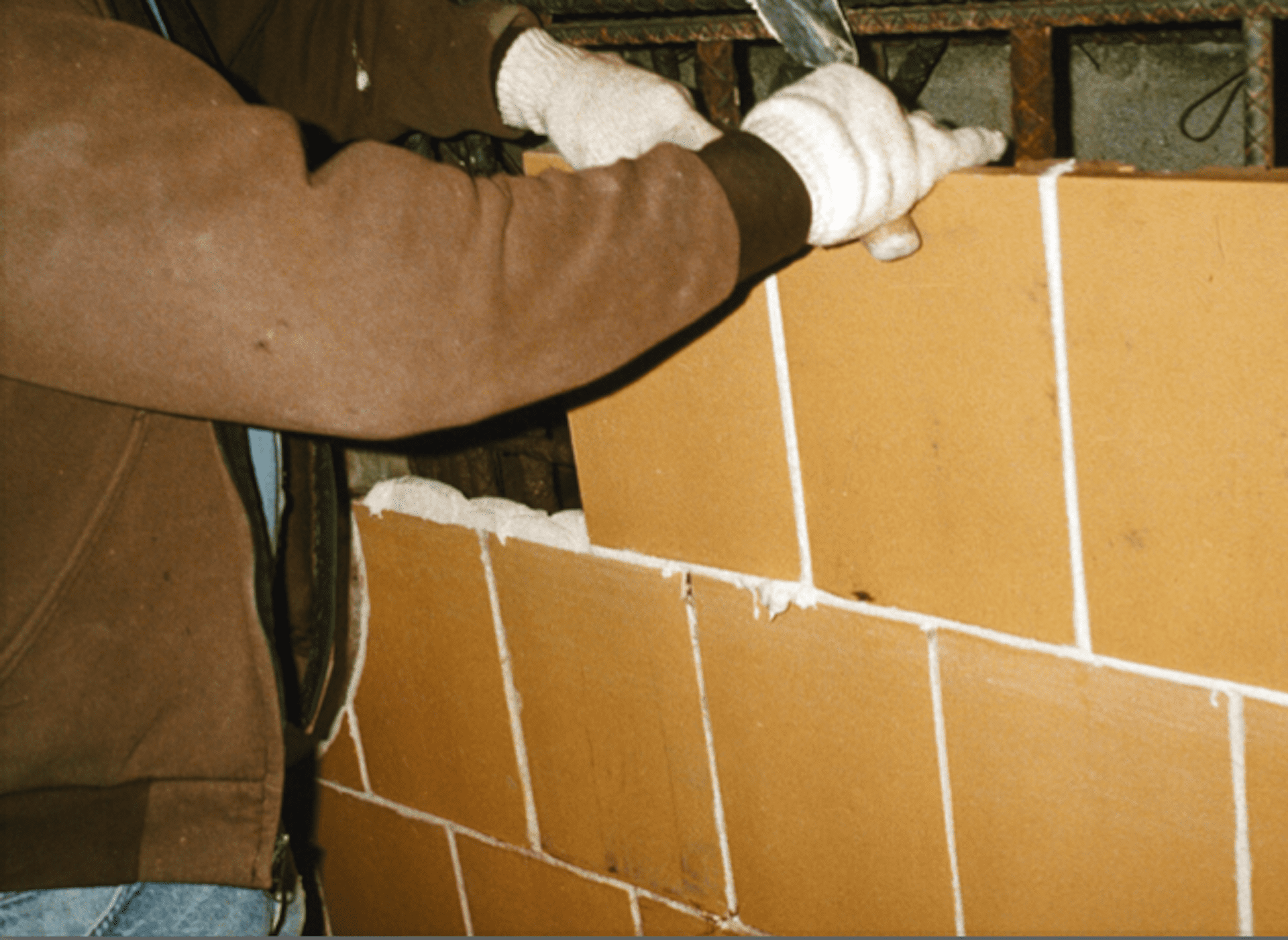

Applying a Vinyl Ester coating requires specialist knowledge and experience. The substrate must be carefully prepared. The coating is then applied in multiple layers using rollers or brushes. In some cases, the system is combined with glass fibre reinforcement for extra mechanical stability.

Want to know more about Vinyl Ester coating?

Are you curious whether a Vinyl Ester coating is suitable for your installation? The specialists at W-Solutions are happy to think along with you.

Please contact us for personal advice or a no-obligation, customized quote.

Interested? Contact us!

Contact us to discover how we can support your project. With our extensive experience and team of experts, we will provide you with the most suitable lining solutions for your assets.

Contact Us!

W-Solutions offers a high-quality solution with the Pennguard Block Lining System for industrial companies looking to protect their installations against the harmful effects of corrosion and extreme temperatures. Thanks to borosilicate blocks, the system is not only strong and durable but also versatile and easy to adapt to the specific requirements of any project. With its unique properties, the borosilicate block in the Pennguard system ensures safe and durable protection of industrial infrastructure, even under the most challenging conditions.

Would you like to learn more about the possibilities of borosilicate block? Contact W-Solutions today!

Our projects

With a global portfolio of over 200 chimneys and projects that have stood the test of time for more than 30 years, Pennguard is recognized as the world’s most proven and reliable chimney lining solution. We invite you to explore and see the impact of Pennguard projects around the world.

Contact us!

Contact us to discover how we can support your project. With our extensive experience and team of experts, we will provide you with the most suitable lining solutions for your assets.